Non-powered Ventilator

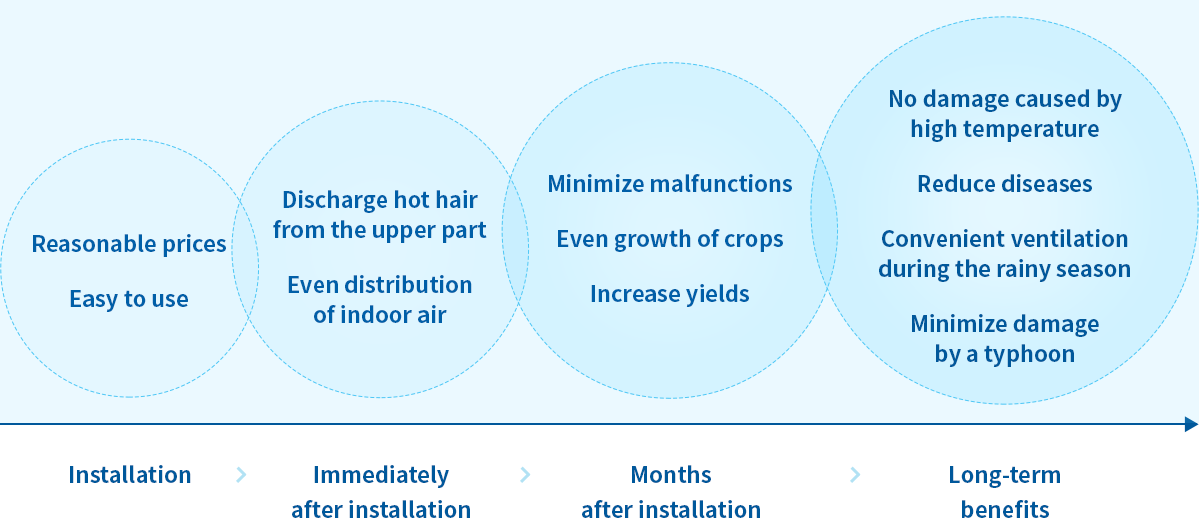

| Product overview |

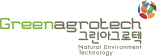

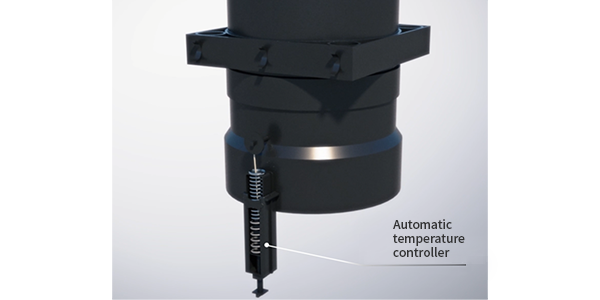

· This fan discharges the heat from the upper part to evenly distribute the indoor air. |

Facility Overview

Facility Overview

Hot air is discharged by convection, helping the crops to grow evenly.

Hot air is discharged by convection, helping the crops to grow evenly.

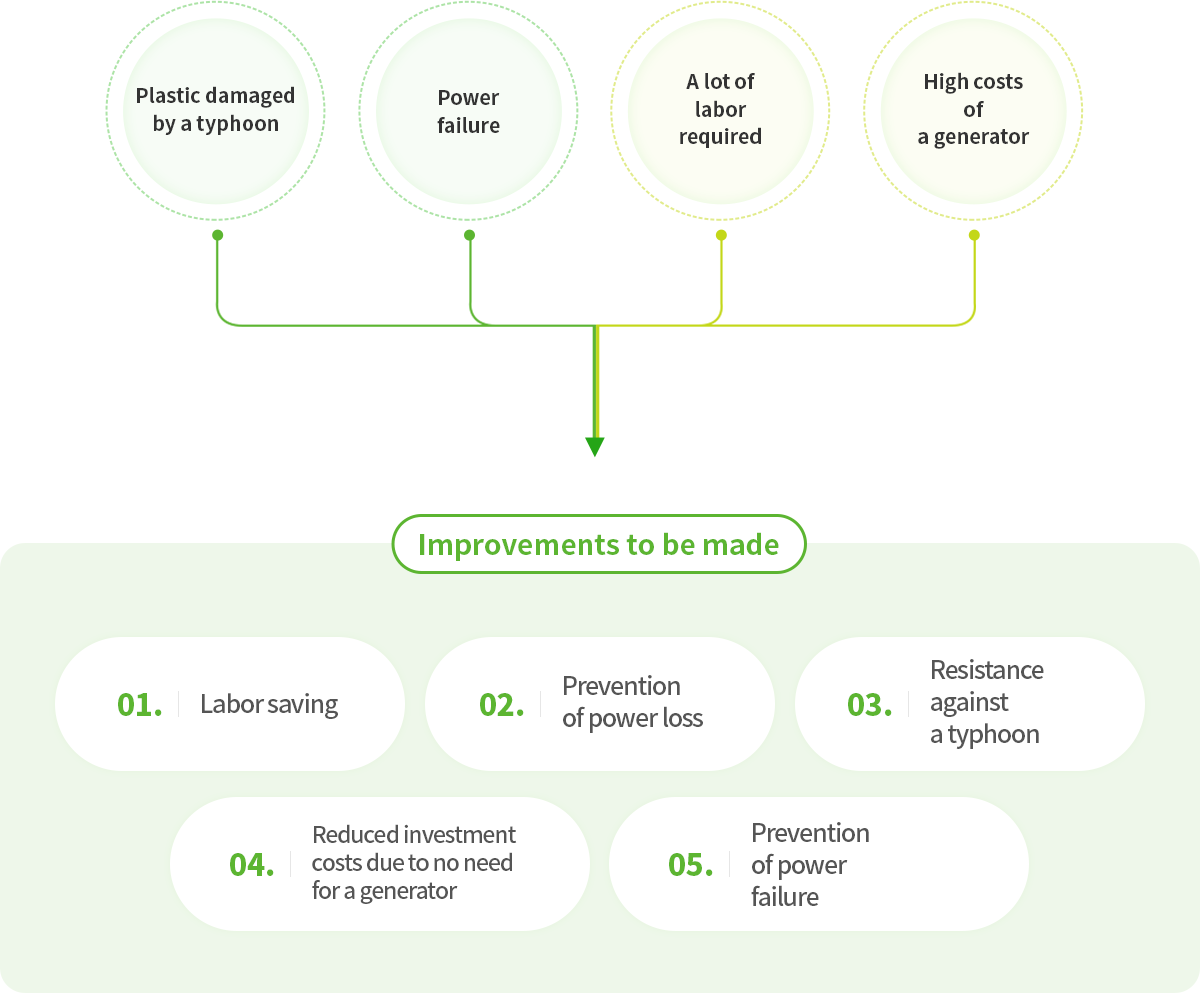

Comparison with the existing system

Comparison with the existing system

| Class. | Existing system | Non-powered automatic temperature control fan |

|---|---|---|

| Comparison |

Operated by electricity (High electricity charge) |

Non-powered mechanical operation, requiring no electricity (No electricity charge) |

| Differences |

Small number of installations due to forced ventilation (for 40 pyeong) Unable to use during typhoon High electricity bills Product prices of KRW 100,000 to 300,000 Lifespan of 2-3 years |

Large number of installations due to no need for power (based on 10 pyeong) No power failure No electricity charge Low installation costs (KRW 40,000~80,000) Semi-permanent lifespan |

| Etc. | Unable to install by the farm due to electrical facilities, etc. |

No use of electricity Easy to install by the farm |

How to Install the Non-powered Fan

How to Install the Non-powered Fan

Installation Examples of the Non-powered Fan

Installation Examples of the Non-powered Fan

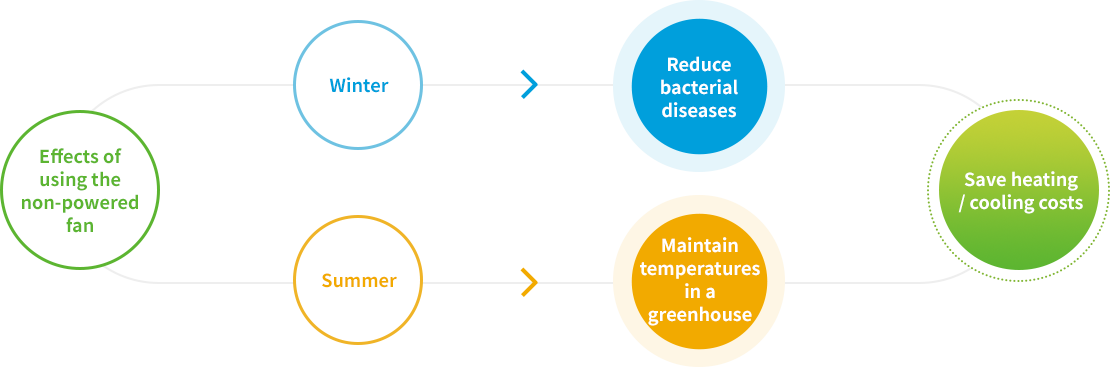

Features of the Non-powered Fan

Features of the Non-powered Fan

Reduce heating costs in winter

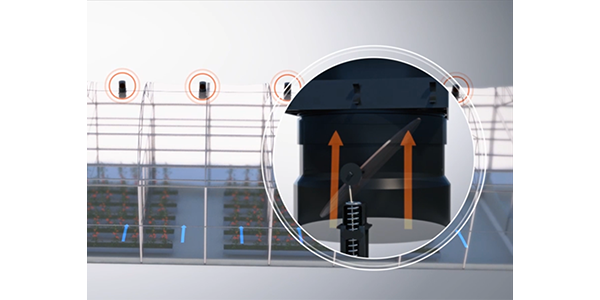

In general, temperature in a greenhouse is kept at 13~20°C depending on the crops but after installing the fan, bacterial diseases are prevented even if the temperature is lowered by 2~5°C. If the non-powered fan is set to 20~22°C, you can maintain the temperature in a greenhouse at 25~29°C without opening the ventilation window until 12:00 a.m.

Prevention of plastic damage during a typhoon

During a typhoon, the rotation speed of the upper fan of the system is increased to 300-800 rotations per minute, and the strong wind increases resistance to prevent damage to the plastic.

Promotion of crop growth

Control of high temperature and sufficient ventilation during daytime prevent high humidity, and the sufficient wind flow prevents unproductive overgrowth of crops.

Prevention of bacterial diseases

Effective ventilation in a greenhouse prevents bacterial diseases caused by poor ventilation and temperature control.

Prevention of high temperature

The hot air in a greenhouse is continuously discharged to prevent damage from high temperatures.

Windowless automation system

Unmanned farming is possible by using a non-powered ventilation fan and non-powered automatic ventilation windows instead of the ceiling ventilation window which needs to be opened/closed manually.

Prevention of damage to a greenhouse caused by a typhoon

Prevention of damage to a greenhouse caused by a typhoon

The non-powered automatic temperature control fan increases the rotation speed per minute (RPM) of the fan to 1300, and thus one non-powered fan can generate ½ horsepower of an electric motor. Based on this principle, the opening unit of the non-powered fan is automatically opened by the wind, and the air inside a greenhouse is discharged to the outside at a high speed. Therefore, the fan prevents a greenhouse from being lifted due to low resistance and thus prevents damage to the plastic.

caused by a typhoon

(Photo by Daejeon Regional Meteorological Administration)

Comparison of damage caused by Typhoon Bolaven in 2012

Reducing heating/cooling costs and extending harvest time

Reducing heating/cooling costs and extending harvest time

Heating of a greenhouse in winter

With the non-powered fan installed in a greenhouse, even if the temperature of the greenhouse is lowered by 4-5°C, bacterial diseases that spread at low temperature and high humidity do not occur easily, which can save heating costs by 30-50% in winter.

Maintaining temperature of a greenhouse in summer

In summer it is very hard to maintain ideal temperatures in a greenhouse, so various cooling devices are used, which may cause an increased economic burden. If the non-powered fan is installed, however, the temperature felt by crops decreases by 6-7℃, so the harvest period is extended by 10-30 days.

Expected results of introducing the fan

Expected results of introducing the fan

Unique benefits of introducing the fan

· In winter, no frost falls in a greenhouse with a fan installed due to the airflow at appropriate temperatures.

· There is no sudden temperature change caused by automatic opening/closing, so ventilation can be performed without affecting the crops.